TOF Long-range Laser Distance Sensor DS Series

DADISICK New Product | TOF Long-range Laser Distance Sensor DS Series

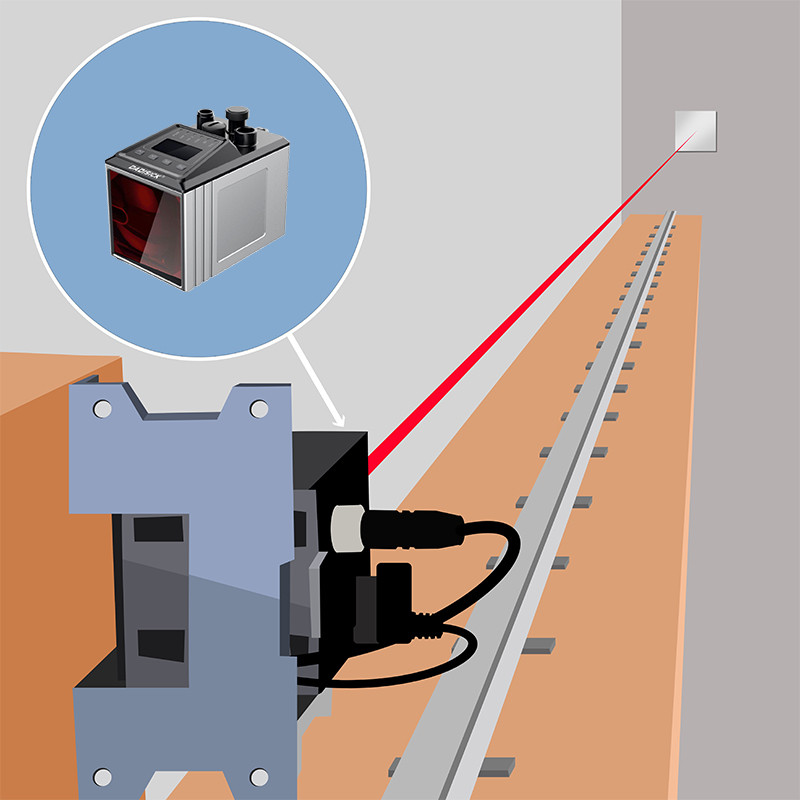

DS Series Long-range Laser Distance Sensor

Specifications

|

Basic Information

|

|||

|

Product Name

|

DS Series Long-Range Laser Distance Sensor

|

||

|

Model

|

DS-80

|

DS-120

|

DS-200

|

|

Measurement Characteristics

|

|||

Measurement Range (with retroreflector) | 80 m | 120 m | 200 m |

Typical Spot Size | 100 mm (@80m) | 150 mm (@120 m) | 245mm (@200 m) |

Measurement Accuracy | ±2 mm | ||

Repeatability | 1 mm | ||

Measurement Frequency | 1000 Hz | ||

Measurement Resolution | 0.1 mm | ||

Maximum Moving Speed | 15 m/s | ||

Optical Characteristics | |||

Supply Voltage | DC 9 V...30 V | ||

Operating Current | 0.2 A/12 V DC | ||

Laser Source | Red Laser (Visible Light) | ||

Power Consumption | 2.4 W (MAX) | ||

Others | |||

Data Transmission Interface | SS1, Ethernet 100BASE-TX | ||

Indicators | PWR Indicator, MF1/MF2 Status, LNK Indicator, BUS Indicator | ||

Display | OLED Screen (128 x 64 pixels) | ||

Network Interface | M12/4-pin/D-type female straight | ||

Power/SSI Interface | M12/8-pin/A-type male straight | ||

Ambient Light Resistance | ≤100,000 lx | ||

Operating Temperature | -10°C ~ +55°C | ||

Storage Temperature | -30°C ~ +75°C | ||

Humidity | <80% | ||

Protection Rating | IP65 | ||

Dimensions | 123 x 69.5 x 90 (mm) | ||

Weight | 600 g (excluding cable) | ||

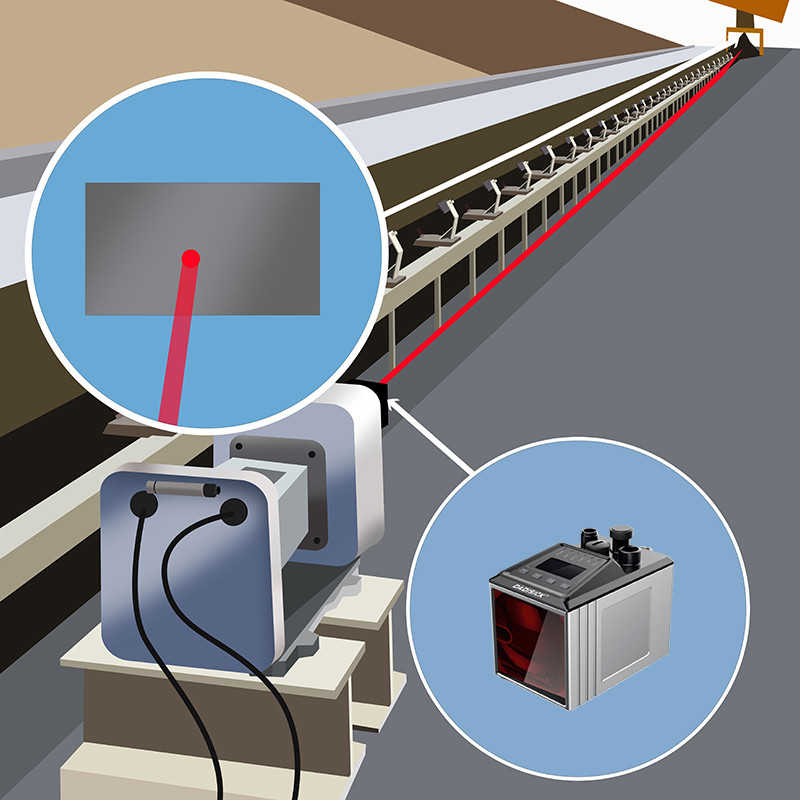

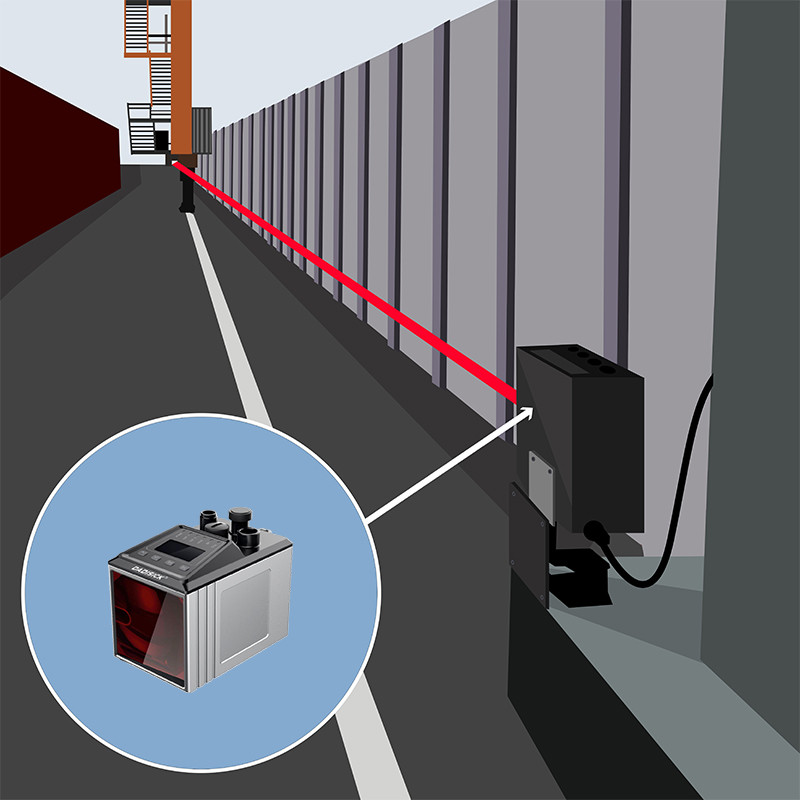

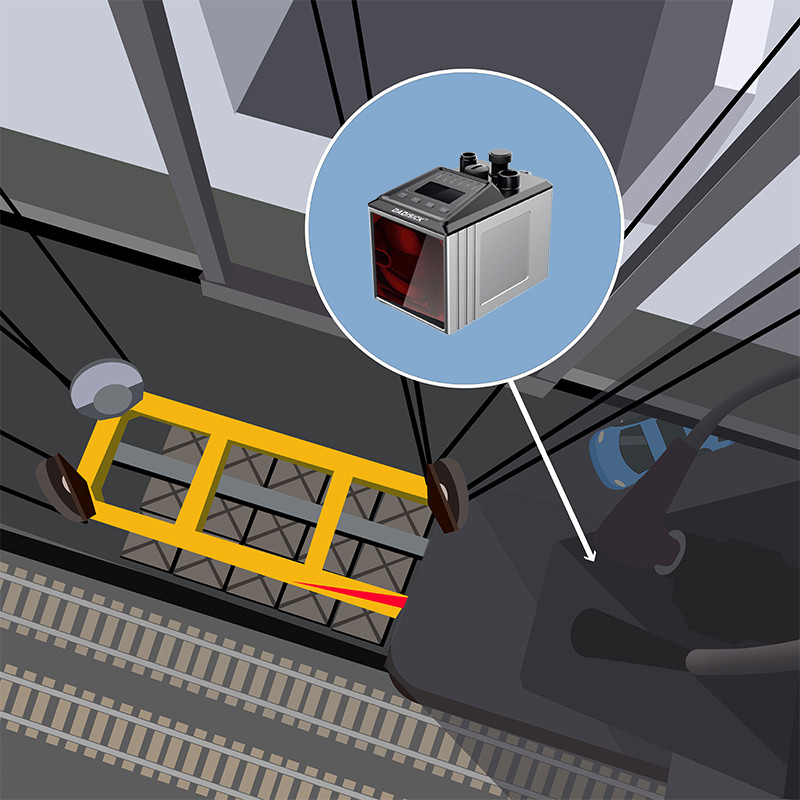

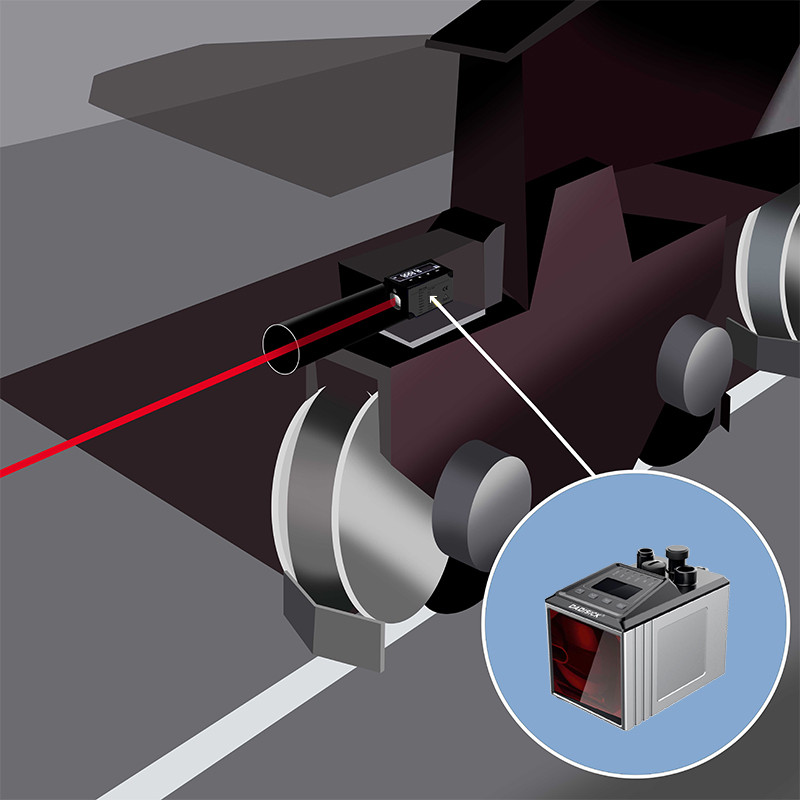

The Application Fields Of The DS Series Laser Displacement Sensors

Crane Collision Prevention in Material Handling

Precise Measurement of Crane Height and Position

Collision Prevention Solution for Gantry Cranes

Precise Positioning of Bridge Cranes in Scrap Yards

Positioning of Stacker and Reclaimer Machines