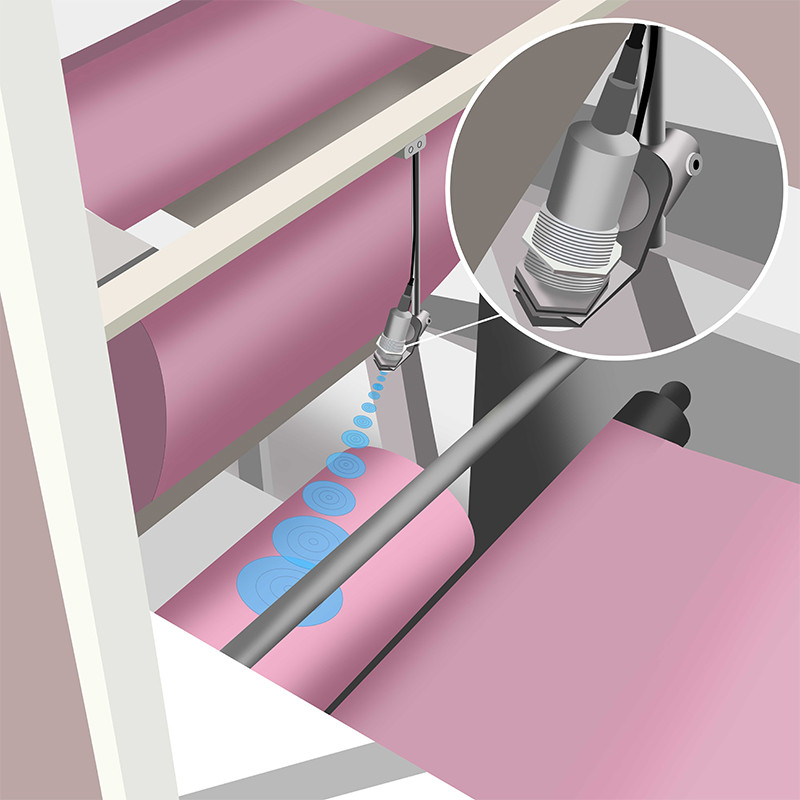

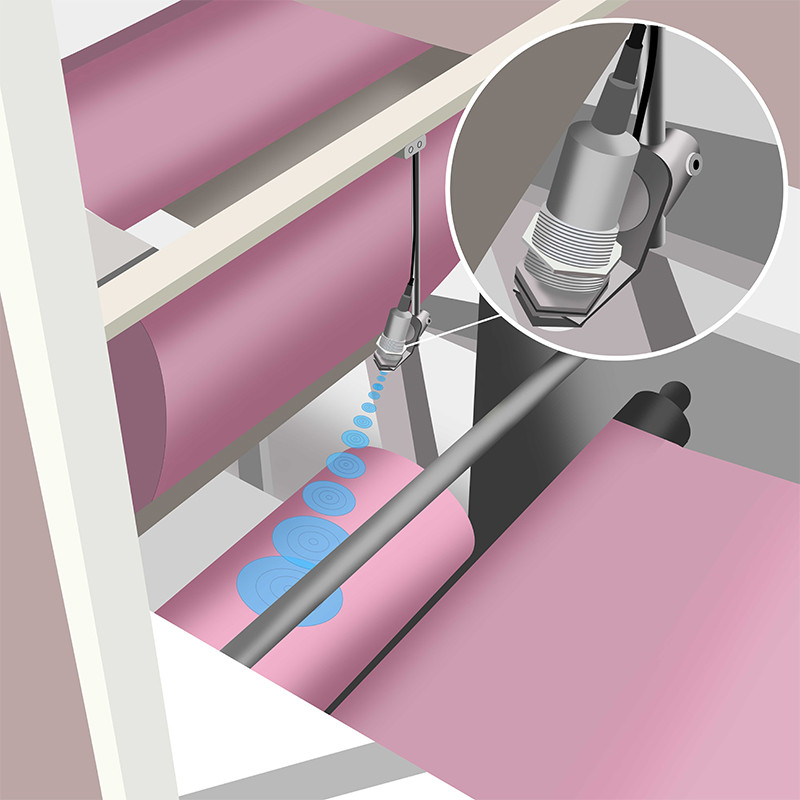

Application of CSB18 Ultrasonic Sensors in Roll Diameter Monitoring

Application of CSB18 Ultrasonic Sensors in Roll Diameter Monitoring

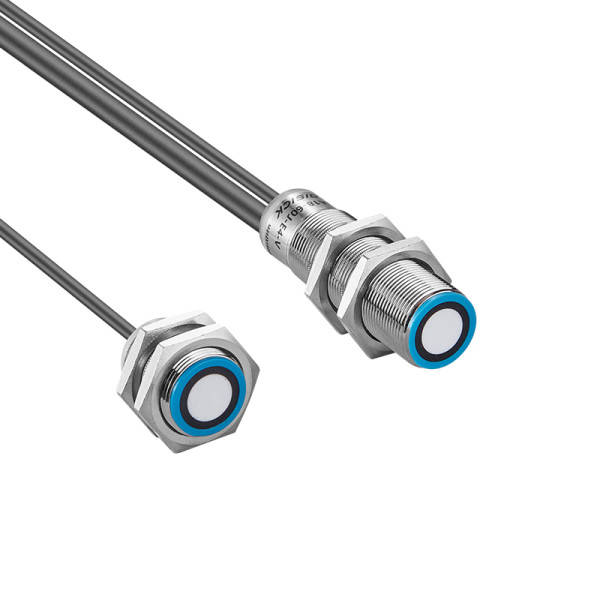

Core Components and Technical Features

|

Models

|

CSB18-300 |

CSB18-500

|

CSB18-1000

|

Detection range | 30-300 mm | 50-500 mm | 60-1000 mm |

|

Blind zone

|

0-30 mm |

0-50 mm

|

0-60 mm

|

|

Resolution

|

0.1 mm |

0.15 mm

|

0.17 mm

|

Response time | 22 ms | 32 ms | 52 ms |

Switching hysteresis | 2 mm | 2 mm | 2 mm |

Switching frequency | 45 Hz | 31 Hz | 19 Hz |

Repeatability: ±0.15% of full-scale value | |||

Absolute accuracy: ±1 % (built-in temperature drift compensation) | |||

Input type: With synchronization and learning function | |||

Output type: Switch output; IO-Link output; Analog output; Digital output RS485 | |||

Material: Copper nickel plating , plastic fittings , glass filled epoxy resin | |||

Connection type: 5-pin M12 connector | |||

Protection Class: IP67 | |||

Ambient temperature: -25°C~+70°C (248~343K) | |||

Intelligent Control System