2D LiDAR Sensors: A Key to Customized and Cost-Effective Solutions

High-Performance Overview of 2D LiDAR Sensors

2D LiDAR Technology Principles

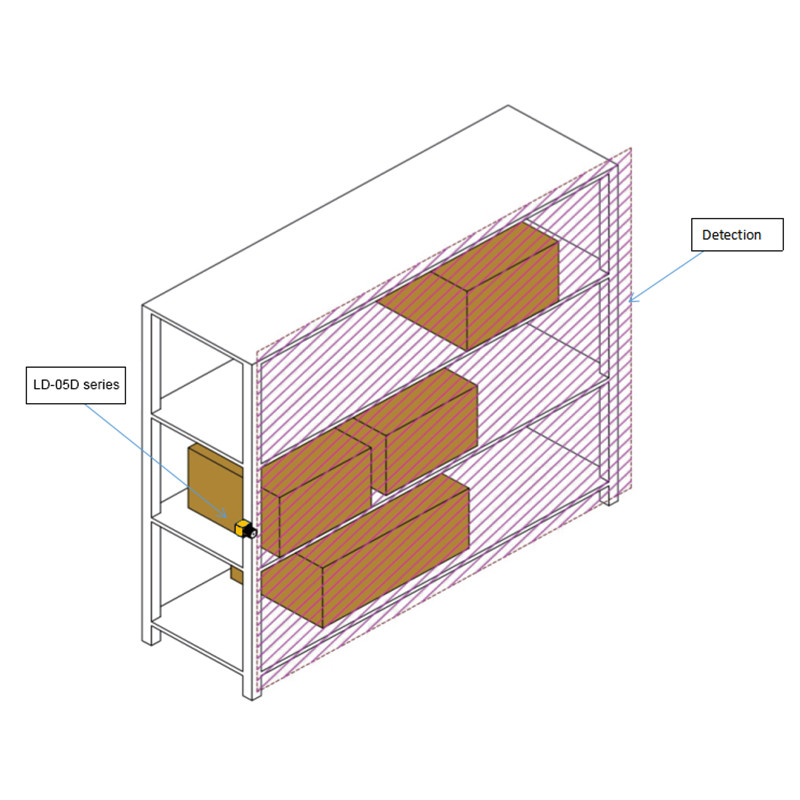

2D LiDAR Sensors Typical Use Case: Protrusion Detection

Compact 2D LiDAR sensor: Customized and Cost-Effective Solutions

|

Technical data

|

||||

|

Working principle

|

Time-of-flight (TOF) measurement principle |

|||

IO output | NPN or PNP | |||

Work area | 0.05 m ~ 5 m | 0.05 m ~ 20 m | ||

|

Laser source

|

905 nm (class I) |

|||

|

Aperture angle

|

270° |

|||

Scanning frequency | 15 Hz / 30 Hz | |||

Angular resolution | 0.1° / 0.3° | |||

Self-learning function | Automatically scan the environment and generate areas | |||

Electrical connections | Db15 Male / Scatter | |||

Supply voltage | DC 9 V ~ 28 V | |||

Power consumption | 2 W | |||

Switch drive | DC 30 V 50 mA max. | |||

Shell color | Yellow | |||

Enclosure rating | IP65 | |||

Weight | 150 g (cable not included) | |||

Dimensions (L × W × H) | 50 × 50 × 76 mm | |||

Detectable object shape | Almost any shape | |||

Measurement error | ±30 mm | |||

Number of field sets | 16 fields, 3 simultaneous protective fields (per field set) | |||

Connection type | Micro-USB | |||

Input | GND/NC × 4 | |||

Switch output | NPN × 3, device working status; PNP × 3, device working status | |||

Delay time | 100 ms ~ 10,000 ms (configurable), typical value 330 ms | |||

Response time | 15 Hz: 67 ms ~ 29,949 ms (configurable), typical value 134 ms; 30 Hz: 33 ms ~ 29,997 ms (configurable), typical value 66 ms | |||

Status Indicator | Status indicator × 1, area group indicator × 3 | |||

Vibration resistance

| 10 - 55 Hz, amplitude 0.75 mm, XYZ three-axis, 2 hours per axis;

50 - 200 Hz, 196 m/s² (20G), scanning speed 2 min/cycle, XYZ three-axis, 2 hours per axis; | |||

Ambient operating temperature | -10 ℃ ~ +55 ℃ | |||

Storage temperature | -30 ℃ ~ +75 ℃ | |||

Ambient light immunity | >15,000 lux | |||