The products here are part of DADISICK's brand product line, which is independently developed, manufactured, and sold.

We provide stable, high-quality products and ensure fast delivery.

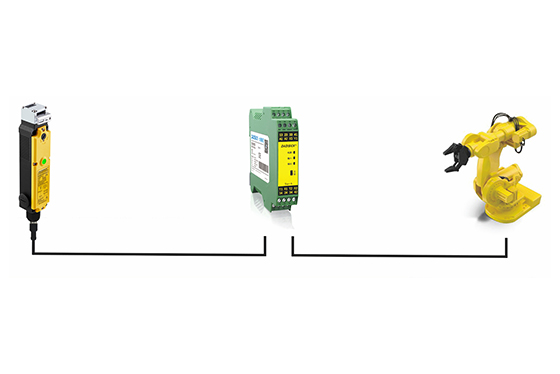

On automated production lines, safety relays can monitor and control the operating status of various mechanical equipment. When abnormal signals are detected, the safety relays will quickly cut off the power supply or trigger other emergency measures to protect the safety of equipment and personnel.

When there are dangerous areas such as rotating machinery and high temperature areas inside the factory, safety relays can monitor these areas by connecting safety sensors. Once a person approaches or enters a dangerous area, the safety relay will immediately trigger an alarm or cut off the power supply of the relevant equipment to prevent accidents.

In automated equipment such as industrial robots, safety relays can monitor the safety status of human-machine interaction through safety sensors. When it detects that the safety distance between humans and robots is insufficient or there are other potential dangers, the safety relay will immediately stop the operation of the robot to avoid personal injury.

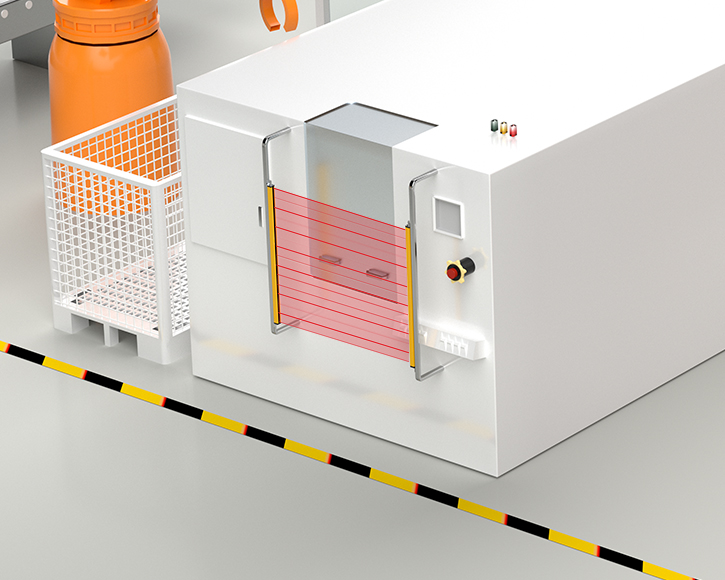

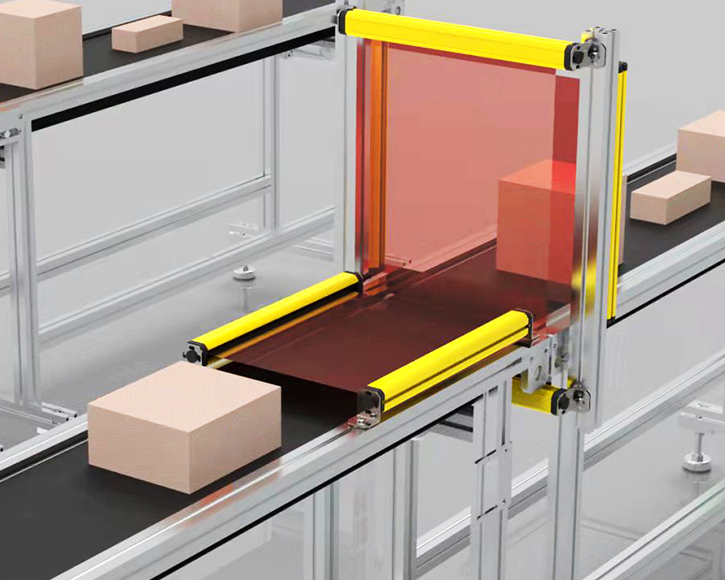

Safety light curtains are an important safety device that provides effective protection for personnel and equipment and helps reduce accidents in the workplace. Safety light curtains consist of a transmitter and a receiver. The transmitter emits multiple light beams, and the receiver receives and detects whether the light beams are complete. When a person or object enters the range of the light curtain, the light beam will be blocked, triggering the safety system to stop operating or take other safety measures.

Safety light curtains are widely used in situations where a safe distance between personnel and machines is required, such as automated production lines, mechanical processing equipment, industrial robots, etc. It can effectively prevent accidents caused by misoperation or accidental contact with dangerous areas.

The safety light curtain uses reflectors to change the transmission direction of light to form a 2-, 3- or 4-sided protection area. It is an efficient and reliable safety protection measure. Through the rational application of this technology, the safety performance of mechanical equipment can be significantly improved and personnel can be protected from injury. It is widely used in various mechanical equipment that require safety protection, such as stamping machines, shearing machines, injection molding machines, robot assembly lines, etc. In these scenarios, mechanical equipment may produce high-speed moving parts or sharp edges during operation. If personnel accidentally enter these areas, serious injuries may occur. Therefore, it is very necessary to install safety light curtains in these areas.

Learn More

As a high-precision, non-contact measuring tool, the measuring light curtain plays an increasingly important role in modern industrial automation. It is suitable for high-precision detection and measurement, including dimension measurement, spray positioning, parts counting, contour detection, precision correction, hole detection, shape detection, edge and center positioning, online product dimension detection, etc. It uses a scanning method, cooperates with the controller and its software, to realize the function of monitoring and measuring the external dimensions of objects.

Learn More

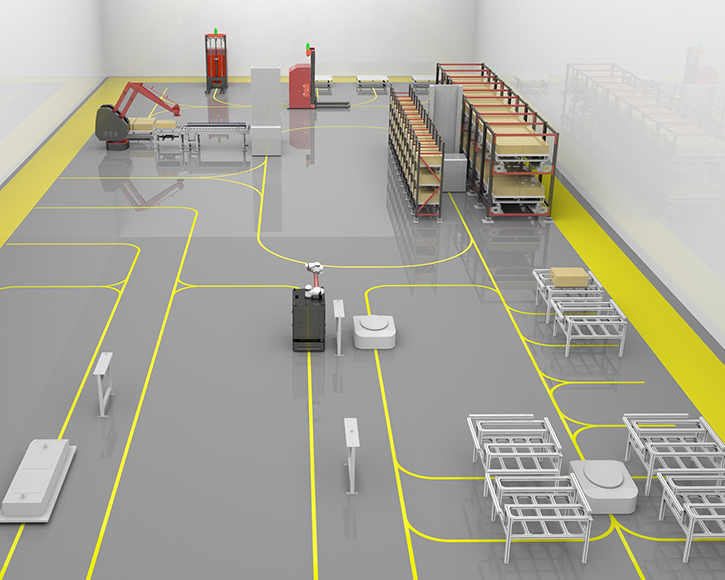

DADISICK laser radar is compact and efficient, with multiple scanning ranges to choose from and affordable. It accurately restores the environment through laser scanning, generates a two-dimensional point cloud map, and intuitively displays object information. It is widely used in robot navigation, AGV obstacle avoidance, factory safety, smart security, and smart transportation. Its high-speed scanning capability helps real-time obstacle avoidance and path planning, and supports custom monitoring areas to achieve accurate security monitoring and improve safety and efficiency.

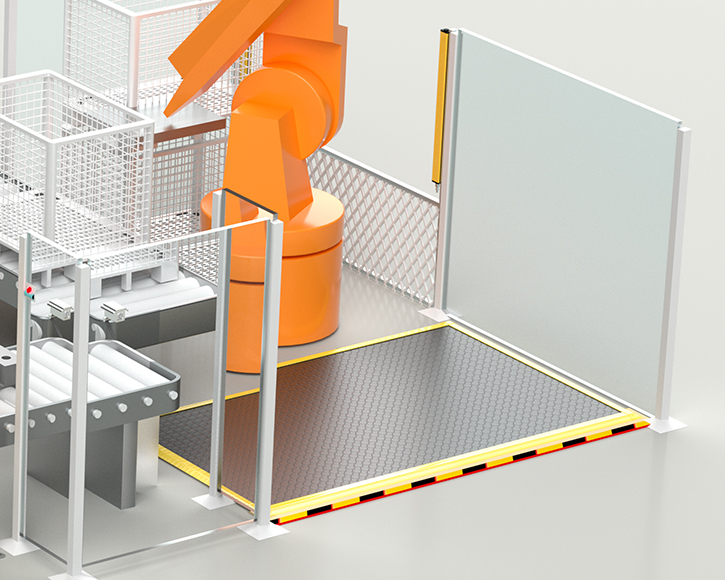

Industrial safety mats and safety edges are devices that achieve safety protection through pressure sensing. They use pressure-sensitive sensor technology. When subjected to a set pressure (i.e. an object of a certain weight), the sensor will trigger a signal to stop the machine from running, thereby protecting the operator from potential dangers.

Learn More

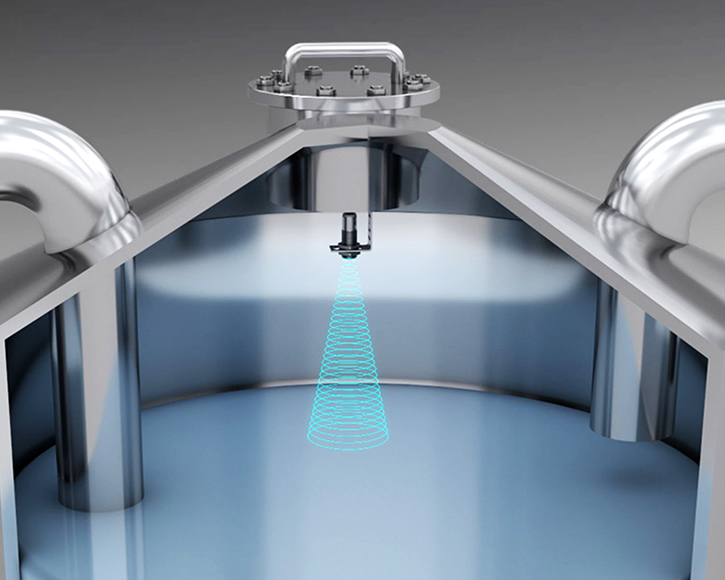

The working principle of ultrasonic sensors is based on the characteristics of sound waves. It first emits high-frequency mechanical sound waves, which are reflected when they encounter objects. By calculating the time or energy between the emission and reception of sound waves, the precise distance or state of the target object can be obtained.

Ultrasonic sensors are also suitable for detecting objects in different states. Whether it is liquid, transparent material, reflective material or particulate matter, ultrasonic sensors can perform effective detection. This makes it widely used in many fields such as industrial automation, robot navigation, liquid level measurement, and obstacle detection.

Laser distance sensors are sensors that use laser technology to measure the position and distance of an object. Based on the working principle of time flight and triangulation, the time it takes to send a laser beam to the target object and back is measured. By measuring the time delay (or phase difference) and the known value of the speed of light, the sensor can calculate the distance between the object and the sensor. It can provide non-contact measurement, and has the characteristics of high accuracy and fast response, and can be integrated with other sensors or systems to achieve more complex measurement and control tasks.

Laser distance sensors are widely used in many fields, including automation, mechanical engineering, manufacturing, intelligent warehousing and logistics, and scientific research. They can be used to measure parameters such as the position, distance, displacement, thickness, shape, surface roughness, etc. of an object.

Used in a variety of applications where access needs to be restricted or accidental activation prevented, safety lock switches are a mechanism that increases safety by preventing accidental or unauthorized use of a particular machine, device, or system.

Depending on the specific application and requirements, safety lock switches can take different forms. With a physical lock or a combination of buttons or switches that need to be engaged to enable or disable the device.

The purpose of a safety lock switch is to reduce the risk of accidents, injuries, or damage that could result from accidental or unauthorized operation. By implementing a safety lock switch, it ensures that only authorized personnel with the appropriate knowledge or credentials can activate or deactivate the device.

For example, in machinery or industrial environments, safety lock switches are often used to prevent accidental startup during maintenance.

Safety relays are widely used and important in industrial equipment. As electrical control devices, they are mainly used to monitor and control safety-related parameters in industrial production processes to ensure the safety of personnel and equipment.

Safety relays detect potential dangerous situations by monitoring input signals (such as signals from safety sensors, emergency stop buttons, etc.), and prevent accidents by controlling output signals when necessary. It is usually used in conjunction with other safety equipment (such as safety gratings, safety sensors, etc.) to form a complete safety control system.