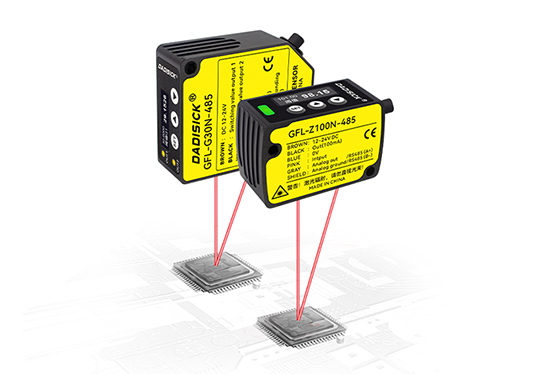

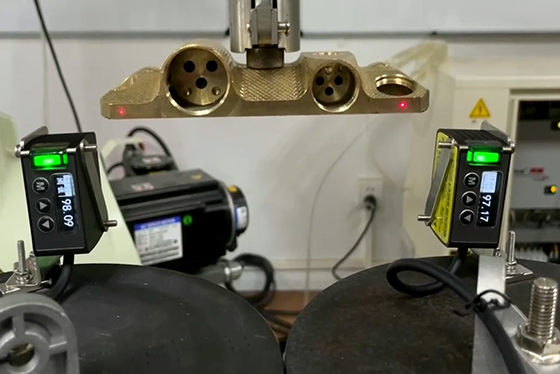

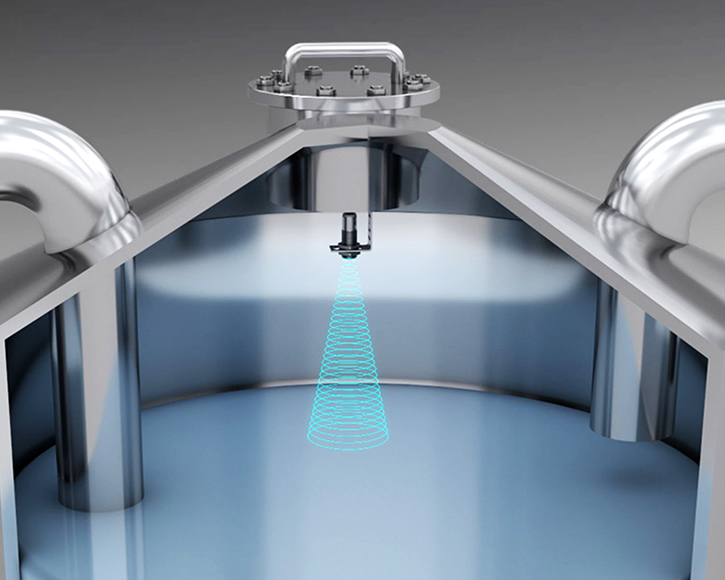

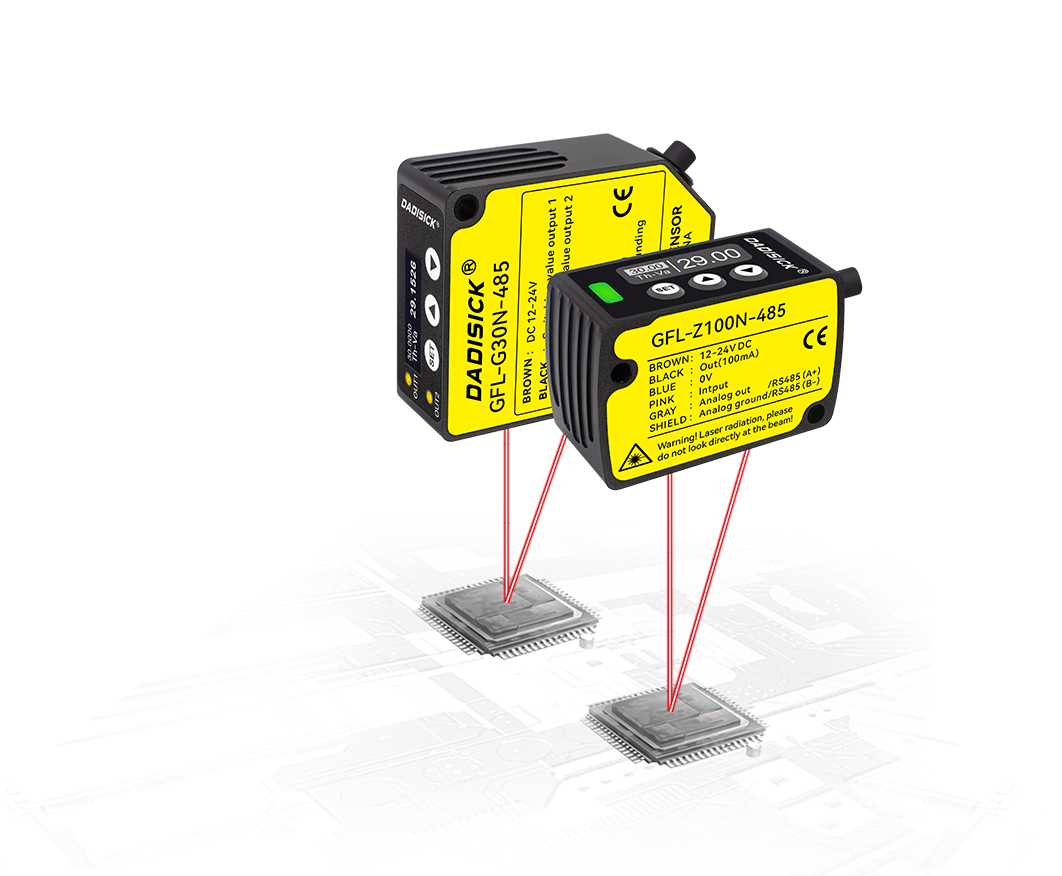

Laser distance sensors are sensors that use laser technology to measure the position and distance of an object. Based on the working principle of time flight and triangulation, the time it takes to send a laser beam to the target object and back is measured. By measuring the time delay (or phase difference) and the known value of the speed of light, the sensor can calculate the distance between the object and the sensor. It can provide non-contact measurement, and has the characteristics of high accuracy and fast response, and can be integrated with other sensors or systems to achieve more complex measurement and control tasks.

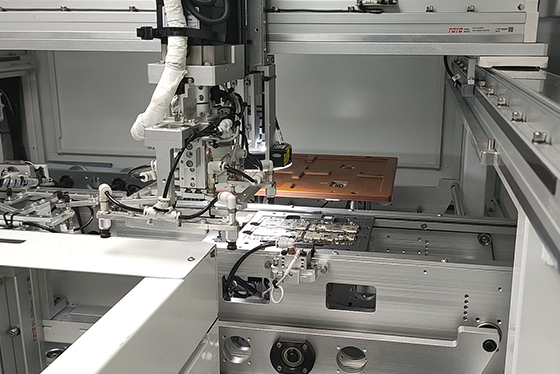

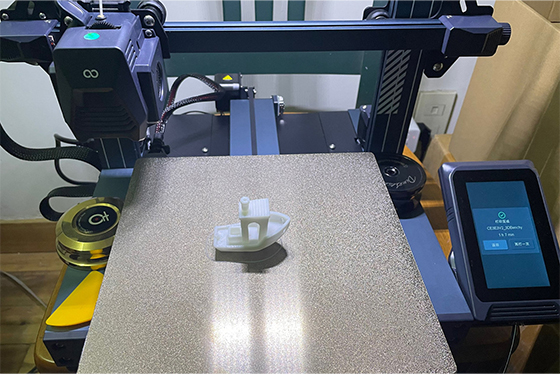

Laser distance sensors are widely used in many fields, including automation, mechanical engineering, manufacturing, intelligent warehousing and logistics, and scientific research. They can be used to measure parameters such as the position, distance, displacement, thickness, shape, surface roughness, etc. of an object.

Learn More