Applications of Laser Displacement Sensors in Precision Position Control and Liquid Level Measurement in 3D Printing

Applications of Laser Displacement Sensors in Precision Position Control and Liquid Level Measurement in 3D Printing

Project Requirements

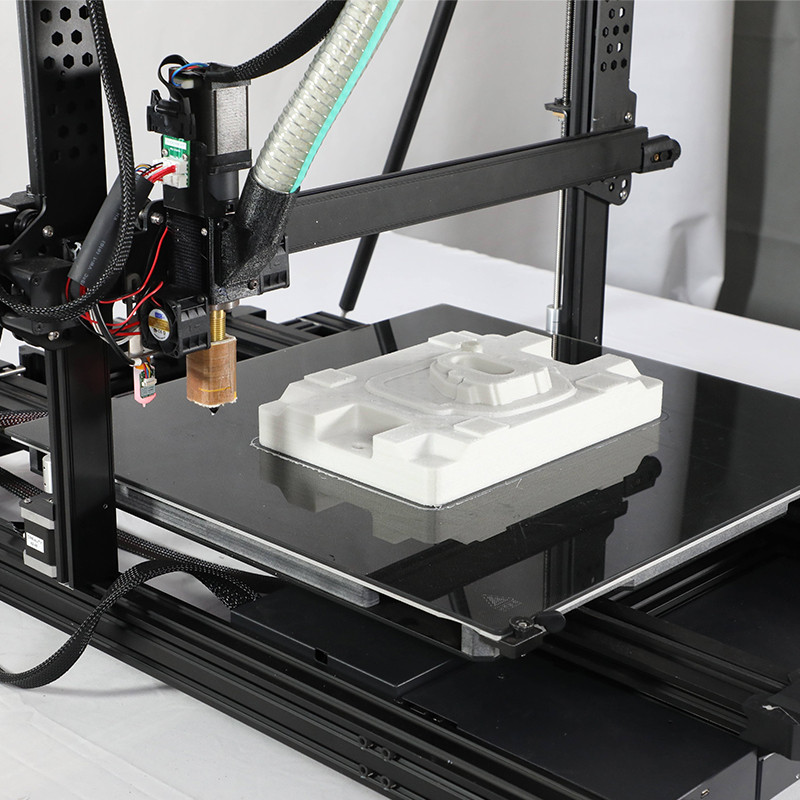

Precise Position Monitoring:

Aimed at achieving precise positioning monitoring of the print platform or laser head/projector head in SLA/DLP 3D printers, ensuring each resin layer is accurately cured at the preset coordinates to maintain print precision and quality.Resin Level Management:

A system needs to be established for efficient monitoring of resin tank levels, preventing print interruptions due to resin depletion and ensuring continuous and efficient production.Precise Position Control Solution:

|

Sensing Distance

|

Resolution

|

Linearity |

Output

|

|

30 mm (±4)

|

2 µm

|

±0.1%f.s. (f.s.=8mm) |

NPN / PNP

Analog RS485 |

|

50 mm (±10)

|

5 µm

|

±0.1%f.5. (f.s.=20mm) |

|

|

85 mm (±20)

|

10 µm

|

±0.1%f.8.(f.s.=40mm) | |

120 mm (±60) | 30 µm | ±0.1%f.s.(f.s.=120mm) | |

250 mm (±150) | 75 µm | ±0.3%f.s.(f.s.=300nm) | |

Advantages of Using GFL-G Series High-precision Laser Displacement Sensors

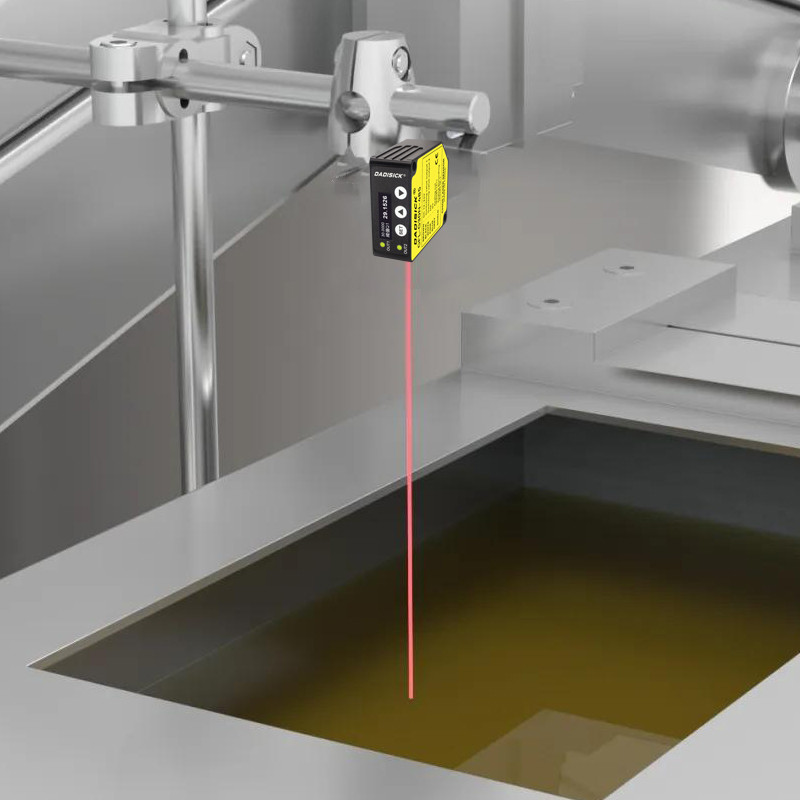

Intelligent Resin Level Monitoring Solution:

|

Sensing Distance

|

Repeatability

|

Linearity |

Output

|

|

30 mm (±5)

|

10 µm

|

±0.1%F.S. |

Analog / RS485

|

|

50 mm (±15)

|

30 µm

|

NPN / Analog / RS485

|

|

|

100 mm (±35)

|

70 µm

|

||

200 mm (±80) | 200 µm | ±0.2%F.S. | |

400 mm (±200) | 400 µm / 800 µm | ||