How Can Cranes Communicate to Prevent Collisions?

How Can Cranes Communicate to Prevent Collisions?

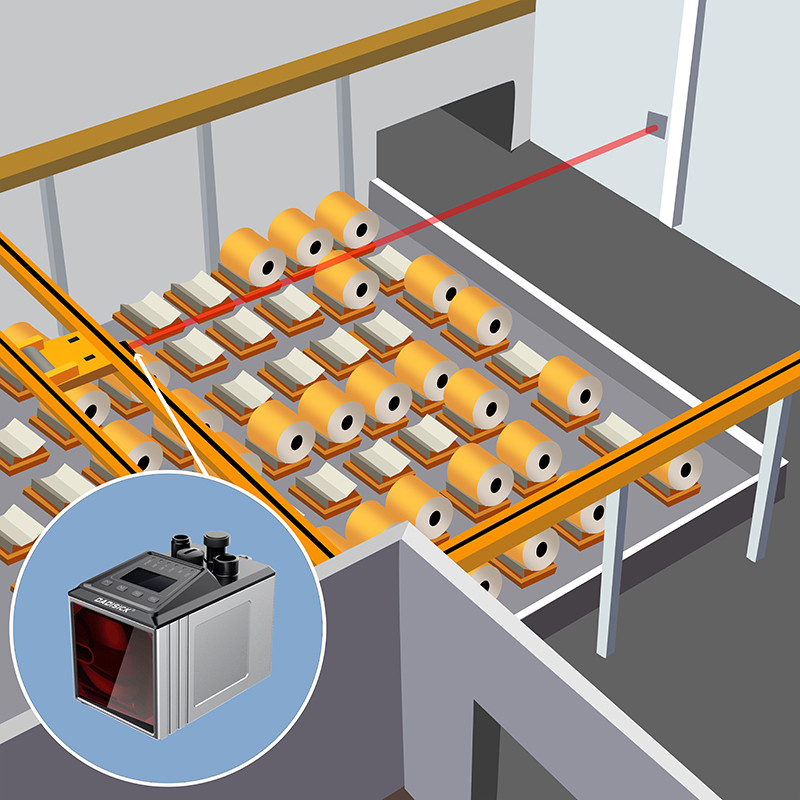

Why Crane‑to‑Crane Communication Matters?

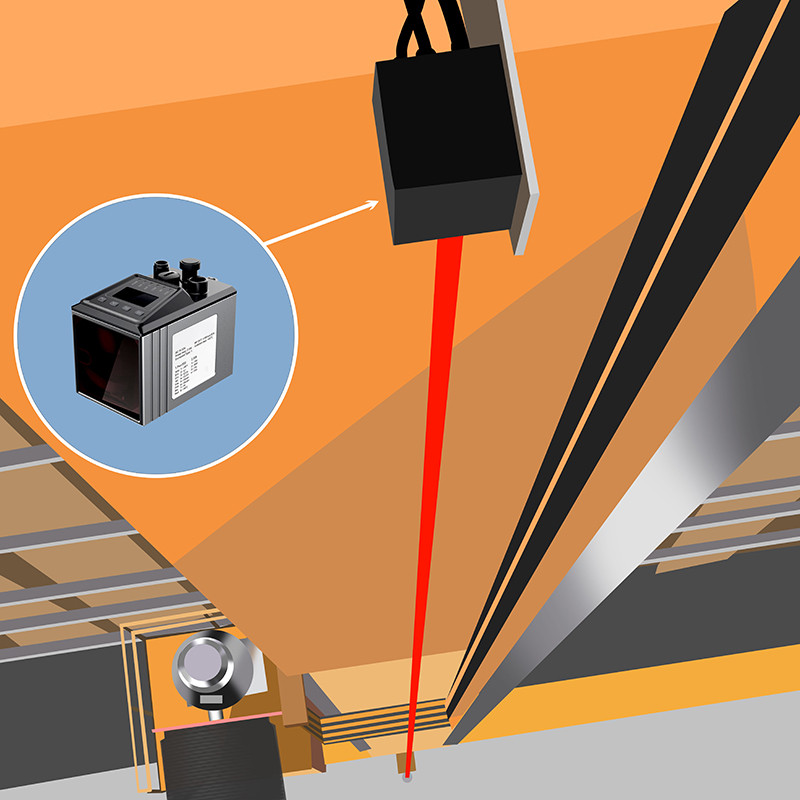

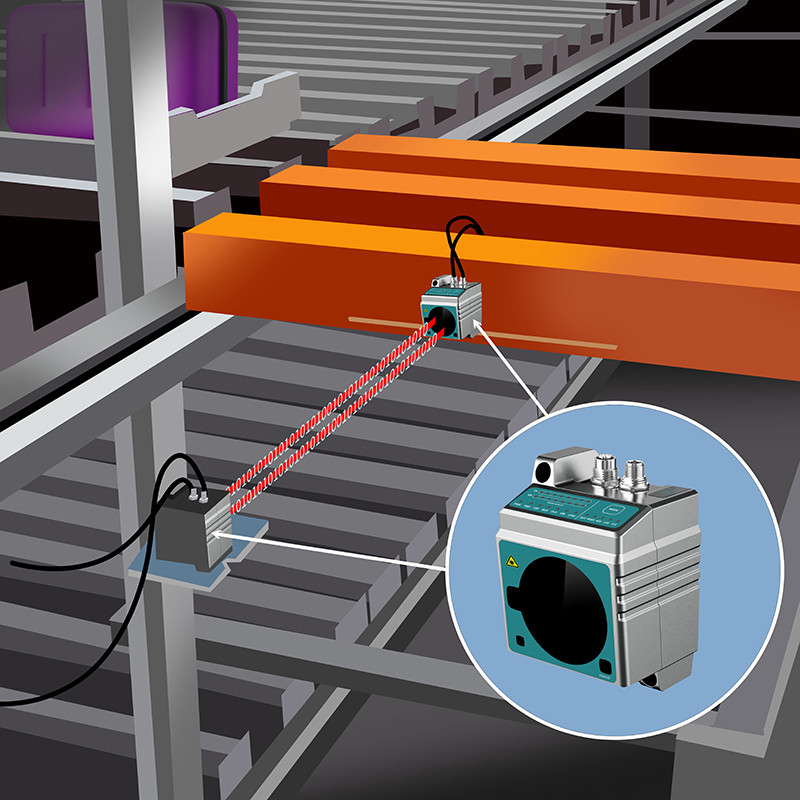

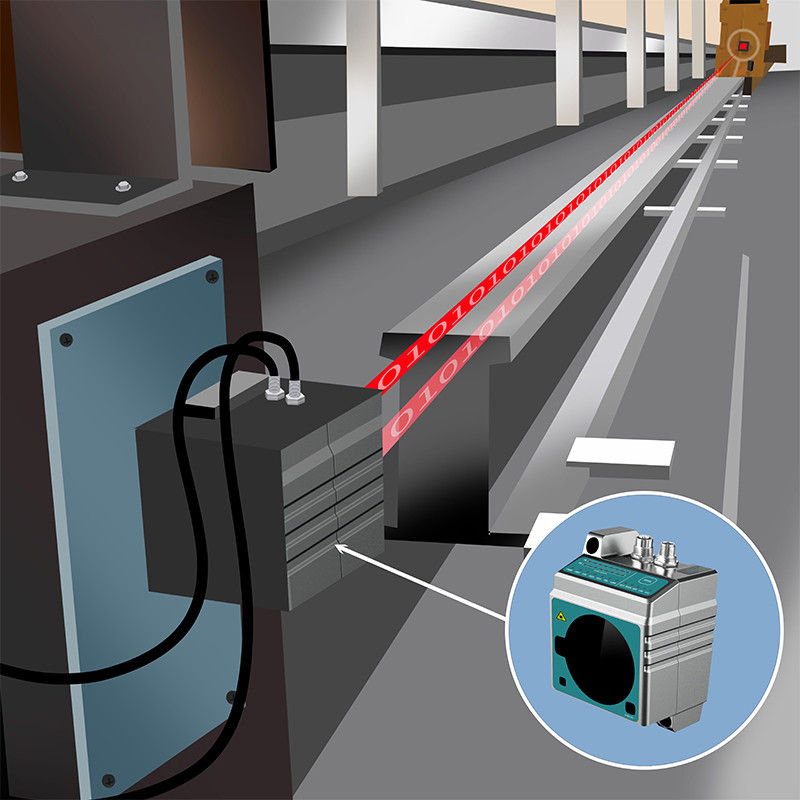

How Does Optical Data Transmission Module Work?

1. Data Encoding & Emission

2. Free‑Space Optical Link

3. Reception & Decoding

Key Benefits:

Advantages of ST100 Optical Data Transmission in Crane Operations

1. Ultra‑Precise Collision Avoidance

2. Real‑Time Control & Diagnostics

3. Robust Performance in Harsh Environments

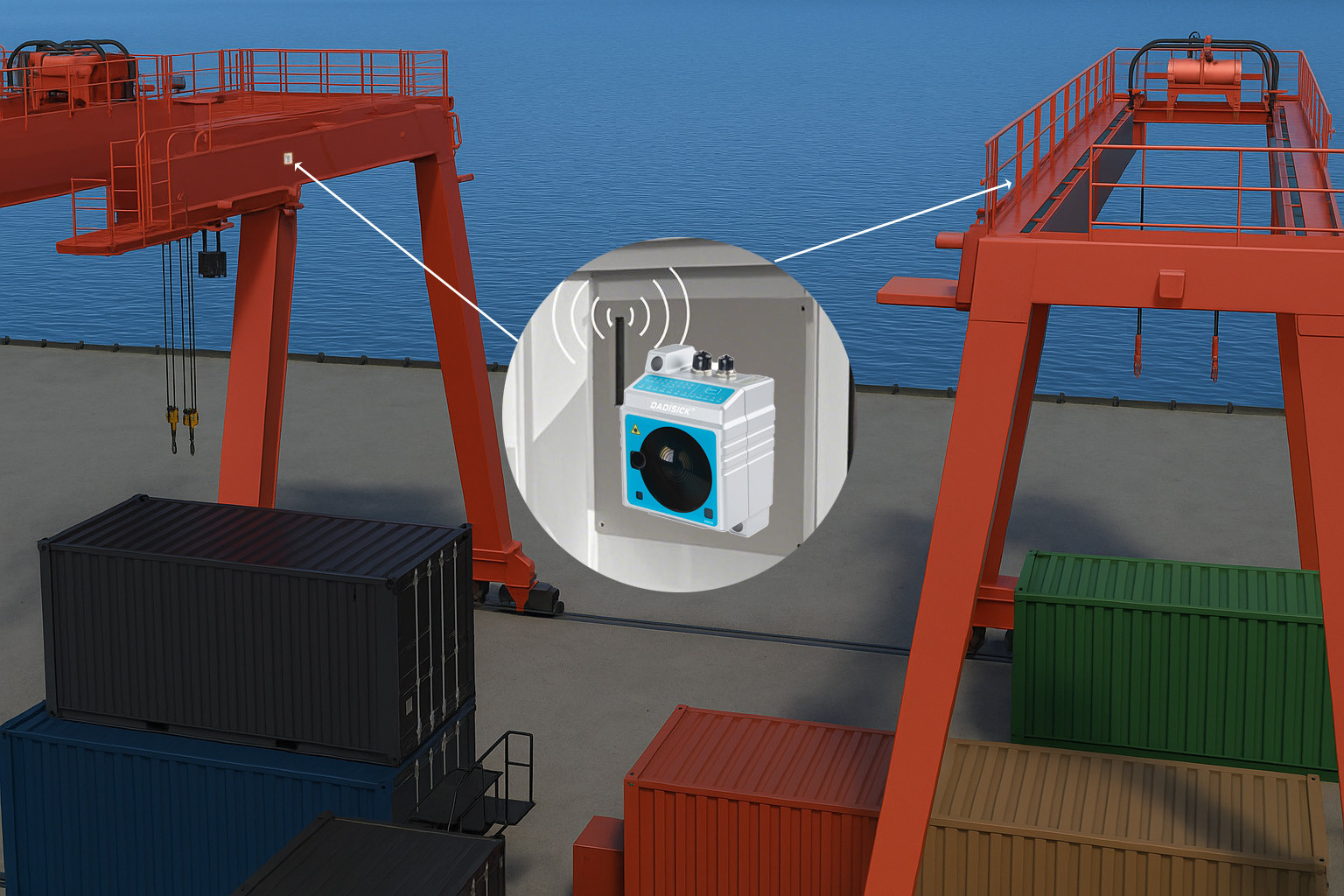

Recommended Optical Data Transmission Module

Optical Data Transmission Module ST100 Series | ||||

| Models | ||||

| Effective transmission distance | 80m | 120m | 200m | |

| Communication rate | 100Mbit/s | |||

| Communication light divergence angle | 1° | |||

Communication light receiving angle | 1.5° | |||

Power supply voltage | DC 10V-30V | |||

Power consumption | 3W (max) | |||

Data transmission interface | Ethernet | |||

Protection level | IP65 | |||

Dimensions | 102 * 84 * 140.5 mm | |||