How Do Different Modes of Photoelectric Switch Sensors Work? A Comprehensive Explanation!

What is a Photoelectric Sensor?

How Do Different Modes of Photoelectric Switch Sensors Work?

Photoelectric Sensors Diffuse Reflective Type

Photoelectric Sensors Specular Reflective Type

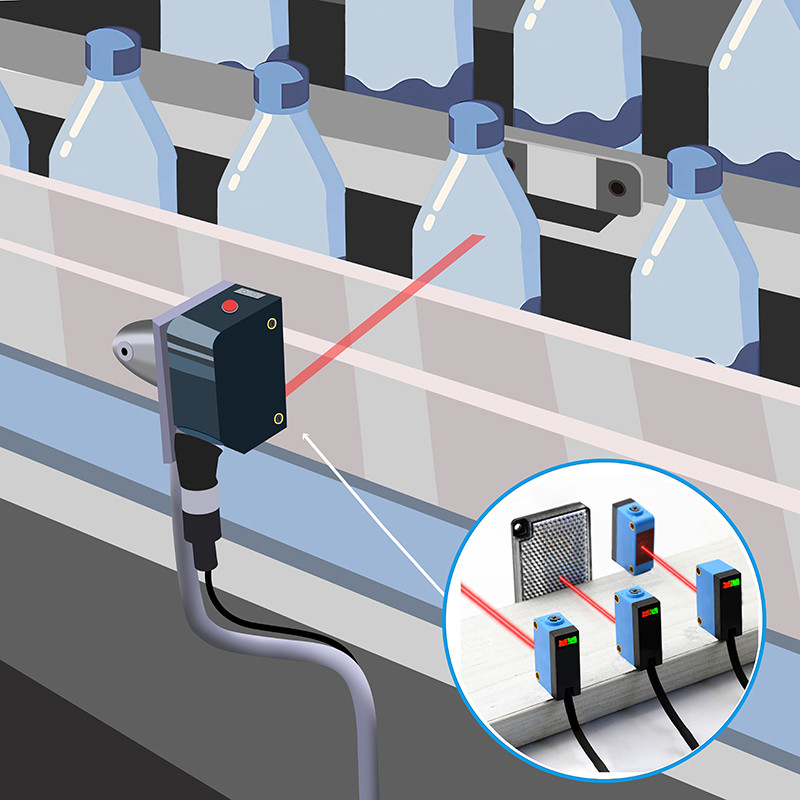

Photoelectric Sensors Through-Beam Type

How to Choose a Photoelectric Sensor?

| Industry | Recommended Type | Typical Case | Technical Key Points |

| Food Packaging | Diffuse + Specular Reflective | Detecting food boxes covered with transparent film | Compensate for film reflection interference |

| Semiconductor Manufacturing | Through-Beam (Fiber-optic) | Wafer transport positioning | 0.01mm repeatable precision, clean environment |

| Steel Metallurgy | Through-Beam (High-temperature type) | Continuous casting billet position detection | High-temperature resistant (>150°C), anti-electromagnetic interference |

Warehousing & Logistics | Specular Reflective (Long Distance) | AGV navigation using reflective boards | 10–30m detection, multi-reflector encoding |

Engineering Details Often Overlooked

Photoelectric Sensors

| Ultra-thin Micro GP13 Series | |||

| Type | Model | Detection range | |

Diffuse Reflective | GP13-03N-ZAA | 2~30 mm (White paper) | |

GP13-03P-ZAA | 2~30 mm (White paper) | ||

Through-Beam (Front detection) | GP13-D30N-ZBA | 300 mm | |

GP13-D30P-ZBA | 300 mm | ||

GP13-D50N-ZBA | 500 mm | ||

GP13-D50N-ZBA | 500 mm | ||

Through-Beam (Side detection) | GP13-L30N-ZBA | 300 mm | |

GP13-L30P-ZBA | 300 mm | ||

GP13-L50N-ZBA | 500 mm | ||

GP13-L50P-ZBA | 500 mm | ||