How to Choose Safety Switches for Factory Equipment Guard Doors?

Applications of Safety Switches

How to Choose the Right Safety Switch?

| Number of Contacts | Safety Level (PL/SIL) | Features | |

| 2 Contacts | PL a/b/c | Basic functionality, suitable for low-risk environments. | |

| 4 Contacts | PL c/d | Dual-channel redundancy, suitable for medium-risk environments. | |

| 6 Contacts | PL d/e | Multi-channel redundancy, suitable for high-risk environments. | |

Recommended Safety Switches

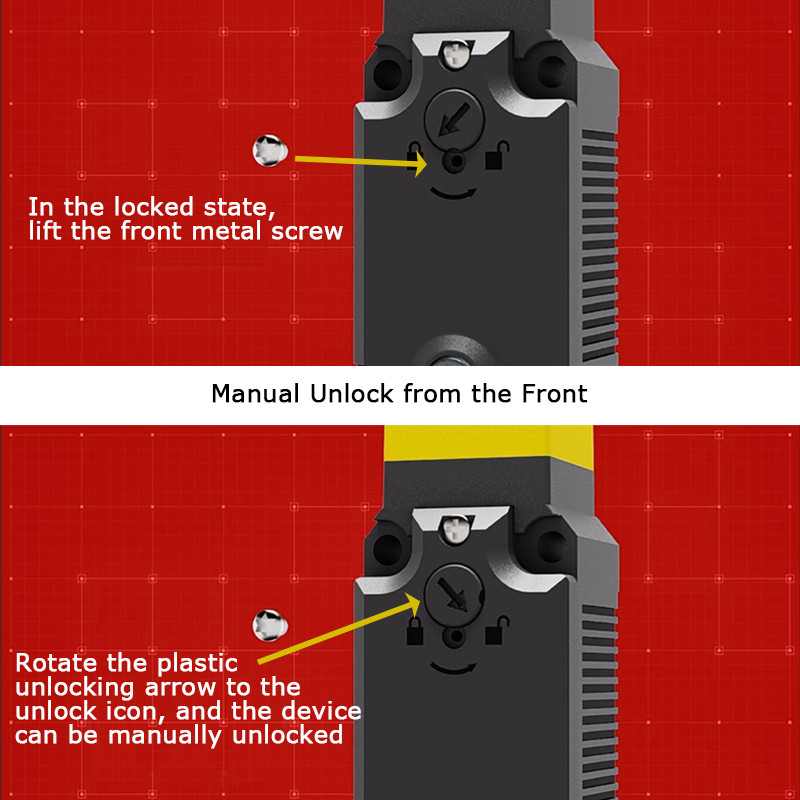

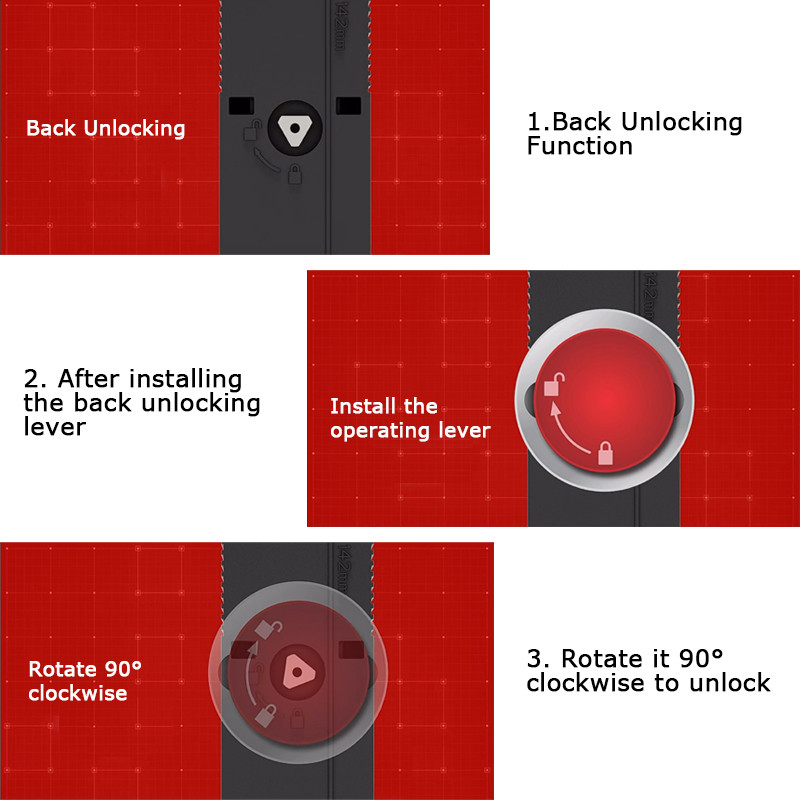

Working Principle and Operating Modes of Safety Switches

|

OX-W2 Series

|

|||||

Lock/Release method | Models | Lock/Release method | Models | Contact composition

(Door + Lock monitoring) | |

Mechanically Locked, Electromagnetically Released | OX-W2-CO/CO-GD-J | Electromagnetically Locked, Mechanically Released | OX-W2-CO/CO-GC-J | CO/CO (1NC/1NO+1NC/1NO) | |

OX-W2-CO/2C-GD-J |

OX-W2-CO/2C-GC-J

|

CO/2C (1NC/1NO+2NC) | |||

OX-W2-2C/CO-GD-J |

OX-W2-2C/CO-GC-J

|

2C/CO (2NC+1NC/1NO) | |||

OX-W2-2C/2C-GD-J |

OX-W2-2C/2C-GC-J

|

2C/2C (2NC+2NC) | |||

OX-W2-C2O/C-GD-J | OX-W2-C2O/C-GC-J | C2O/C (1NC/2NO+1NC) | |||

OX-W2-3C/C-GD-J | OX-W2-3C/C-GC-J | 3C/C (3NC+1NC) | |||

OX-W2-2CO/C-GD-J | OX-W2-2CO/C-GC-J | 2CO/C (2NC/1NO+1NC) | |||

OX-W2-C/3C-GD-J | OX-W2-C/3C-GC-J | C/3C (1NC+3NC) | |||

OX-W2-C/C2O-GD-J | OX-W2-C/C2O-GC-J | C/C2O (1NC+1NC/2NO) | |||

OX-W2-C/2CO-GD-J | OX-W2-C/2CO-GC-J | C/2CO (1NC+2NC/1NO) | |||

OX-W2-O/3C-GD-J | OX-W2-O/3C-GC-J | O/3C (1NO+3NC) | |||

OX-W2-O/2CO-GD-J | OX-W2-O/2CO-GC-J | O/2CO (1NO+2NC/1NO) | |||

OX-W2-2C/2O-GD-J | OX-W2-2C/2O-GC-J | 2C/2O (2NC+2NO) | |||

OX-W2-2O/2C-GD-J | OX-W2-2O/2C-GC-J | 2O/2C (2NO+2NC) | |||

|

OX-W3 Series

|

|||||

Lock/Release method | Models | Lock/Release method | Models | Contact composition

(Door + Lock monitoring) | |

Mechanically Locked, Electromagnetically Released | OX-W3-C/C-GD-J | Electromagnetically Locked, Mechanically Released | OX-W3-C/C-GC-J | C/C (1NC+1NC) | |

OX-W3-/2C-GD-J |

OX-W3-/2C-GC-J

|

/2C (2NC) | |||

OX-W3-2C/-GD-J |

OX-W3-2C/-GC-J

|

2C/ (2NC) | |||

OX-W3-CO/-GD-J |

OX-W3-CO/-GC-J

|

CO / (1NC/1NO) | |||

OX-W3-O/C-GD-J | OX-W3-O/C-GC-J | O/C (1NO +1NC) | |||

OX-W3-/CO-GD-J | OX-W3-/CO-GC-J | /CO (1NC/1NO) | |||

|

OX-W5 Series

|

|||||

Lock/Release method | Models | Lock/Release method | Models | Contact composition

(Door + Lock monitoring) | |

Mechanically Locked, Electromagnetically Released | OX-W5-2CO/2CO-GD-J | Electromagnetically Locked, Mechanically Released | OX-W5-2CO/2CO-GC-J | 2CO/2CO(2NC/1NO+2NC/1NO) | |

OX-W5-3C/2CO-GD-J |

OX-W5-3C/2CO-GC-J

|

3C/2CO (3NC+2NC/1NO) | |||

OX-W5-2CO/3C-GD-J |

OX-W5-2CO/3C-GC-J

|

2CO/3C (2NC/1NO+3NC) | |||

OX-W5-3C/3C-GD-J |

OX-W5-3C/3C-GC-J

|

3C/3C (3NC+3NC) | |||