Since 2006, DADISICK has led industrial automation safety tech globally. We specialize in smart sensor solutions, prioritizing safety, efficiency, and innovation

SENSOR PRODUCTS

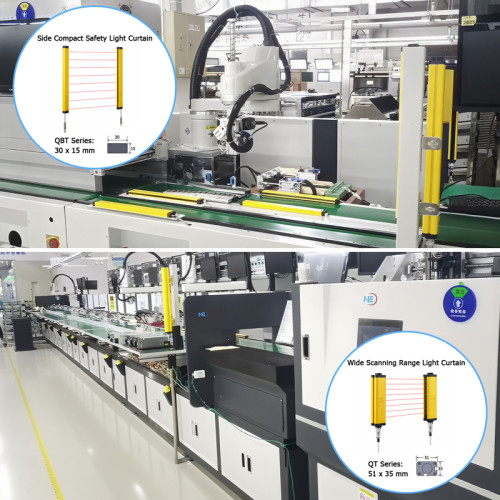

- Safety Light Curtains General Purpose|QCE SeriesThe Wide Scanning Range|QT SeriesEliminating Dead Zones|QO SeriesWaterproof|QRF SeriesEconomical|KT SeriesMulti-Sided Access Protection|QSA SeriesSide Compact|QBT SeriesFront Ultra-Thin|QZ SeriesHigh-precision|QM SeriesCascade light curtain|QT4 Series