Customer Background:

A manufacturing company relies on robotic arms to accelerate their production processes and increase efficiency. However, the multi-axis accessibility of the robotic arms poses safety challenges during operation. The customer needed a reliable solution to ensure that the robotic arms would not pose a danger to personnel or nearby objects during their movements.

The multi-axis accessibility of robotic arms in a factory environment means that they can move in different directions and heights, increasing the risk of collisions and accidents. The customer needed a reliable safety measure that could promptly detect any potential hazards and trigger an emergency stop or slowdown of the robotic arms.

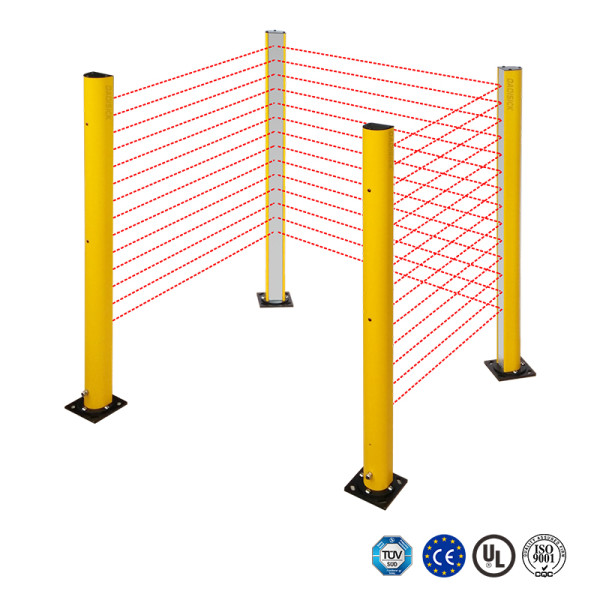

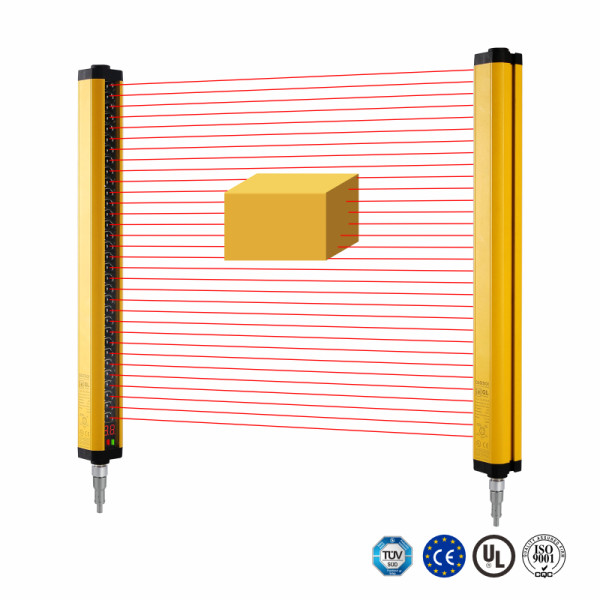

Solution: DADISICK QSA26/40-1000 2B3L Safety Light Curtains

DADISICK's engineering team recommended the use of QSA26/40-1000 2B3L safety light curtains, which are advanced safety devices specifically designed for multi-axis access protection.

Implementation and Results

After the installation of DADISICK QSA26/40-1000 2B3L safety light curtains, the customer achieved the following key outcomes:

1.Enhanced Operational Safety:

The safety light curtains effectively protected the multi-axis access paths of the robotic arms, reducing the risk of collisions and accidents and enhancing operational safety.

2.Improved Production Efficiency:

Because the safety light curtains could promptly detect potential hazards and trigger emergency stops or slowdowns of the robotic arms, the production process became smoother, with less frequent shutdowns and inspections.

3.Cost Savings:

By avoiding collisions and accidents, the customer reduced maintenance and repair costs, extending the lifespan of their equipment.