Our client is located in Mexico and is a professional printing equipment manufacturer. They produce various printing equipment, including large printing presses. In the operation of printing equipment, employees need to interact closely with the machines, and the high-speed operation of the machines also brings potential safety risks. The client needs a way to improve the safety of operations and reduce the risk of potential accidents.

The installation process of printing machinery usually involves complex machine movements and adjustments, and employees need to interact closely with the machines during this process. In this case, ensuring the personal safety of employees is crucial. Our client, a printing equipment manufacturer, also faces this challenge.

Our client is a professional woodworking machinery manufacturer that produces various types of woodworking machines, including sawing machines, planers, and woodworking lathes . These machines often involve rotating knives and other dangerous parts, so ensuring the safety of operators is crucial. The client needs an effective way to improve safety and prevent potential accidents.

Printing equipment usually involves high-speed rotating parts and moving machinery, which poses potential safety risks. To ensure the safety of employees, manufacturers and printing shops need to take a series of safety measures. The safety zone requires an additional layer of protection to provide isolation in front of the hazardous area.

Our customer is a professional manufacturer of printing coating machines, dedicated to producing efficient printing and coating equipment. These machines are typically operated at high speeds, involving hazardous components such as rotating drums and coating nozzles. They recognized the importance of providing additional safety protection for operators.

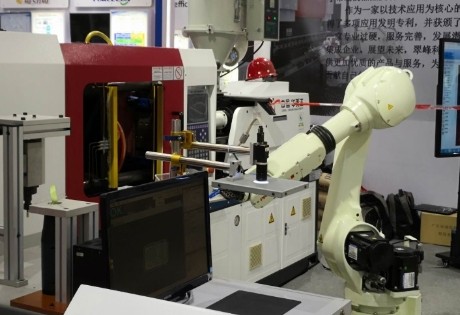

Our client is a specialized manufacturer of automated equipment, producing automated production lines, robotic workstations, and intelligent logistics systems. These automated devices play a critical role in various industries, offering high efficiency and productivity. However, safety has always been a major concern for them since these devices typically operate at high speeds, requiring the assurance of the safety of operators and those around them.

Our client is a specialized packaging and transportation company dedicated to efficiently moving goods from production locations to their destinations. Their operations involve various equipment and machinery, including conveyors, loading and unloading machines, and packaging equipment. Due to the complexity of operations and involvement of high-speed movements, they realized the need for an effective way to ensure employee safety.

Our client is an industrial manufacturing company that extensively employs fixed conveyor systems to automate their production processes. These systems often involve high-speed operations and handling large volumes of materials. To protect their employees and maintain production efficiency, they needed a reliable safety solution.

Our client is a specialized packaging and logistics company responsible for packaging and distributing various products to customers. Their packaging lines typically operate at high speeds, requiring workers to closely collaborate with machines and equipment. Therefore, they needed a reliable method to ensure worker safety while maintaining high-efficiency production.

Our client is a specialized packaging and logistics company providing packaging, loading and unloading, and transportation services worldwide. Their operations often span multiple locations and require authorized access management to ensure the safety of their work environment.

Our client is a logistics giant specializing in goods sorting and transportation. They operate large-scale belt conveyor systems globally to meet the growing demands of logistics. With the expansion of their business, they began to focus on the safety of their operations, especially when interacting with automated belt conveyor systems.

Our client is a large packaging company, processing a substantial volume of products every day, with timely delivery being critical. However, they realized that while striving for high-efficiency production, they must pay greater attention to worker safety, especially during packaging line operations.

Our client is a specialized metal processing company using automatic tube bending machines to manufacture various bent metal components. These machines require high precision in operation but also pose potential risks, especially when there is a chance of personnel or other objects accidentally entering the operating area.

Our client is a leading motor manufacturing company, specializing in the production of various motors for different industrial applications. Their motor winding machines are a critical part of the manufacturing process, used to precisely wind copper wires onto the stators and rotors of motors to ensure their electrical performance.

Our client is a company that manufactures industrial equipment, and their production lines have some potential hazardous areas that require ensuring a safe distance between operators and machinery. They had been searching for an advanced safety technology to enhance the safety of these hazardous areas.

Our client is a specialized laser cutting and engraving company that works with a variety of materials, including metals, wood, plastics, and acrylics. Laser cutting machines are their primary production equipment, but these machines can pose potential hazards during operation.

Our customer is a specialized manufacturer of high-precision equipment, including polishing machines used for surface treatment of various workpieces. Due to the involvement of rotating and high-speed moving parts in polishing machine operations, safety has always been a major concern for them.

A leading manufacturer of automated equipment dedicated to producing highly intelligent and automated machines to enhance production efficiency.

A company specializing in the manufacturing of intelligent Automated Guided Vehicle (AGV) carts, widely used in the field of automated warehousing and logistics.

A manufacturing company actively adopting robotic technology to improve production efficiency and reduce manual labor. They needed a reliable method to ensure the safety of operators and other personnel in the robot's workspace during operation.

A plastic products manufacturing company specializing in injection molding production. They operate multiple injection molding machines and produce a significant volume of plastic products daily. Therefore, safety is one of their top concerns.

A large container terminal company located in a port city has been searching for a reliable solution to enhance the safety and efficiency of their crane operations. Their main challenge was to ensure that cranes would not collide with other vehicles, cargo, or personnel in the busy port environment.

The customer in this case is a highway management authority responsible for overseeing a busy highway with thousands of vehicles passing through daily. They face challenges in managing traffic, ensuring road safety, and accurate toll collection.

A logistics company with large warehouses that require an emergency stop mechanism for their warehouse doors to ensure the prevention of accidents during door operation.