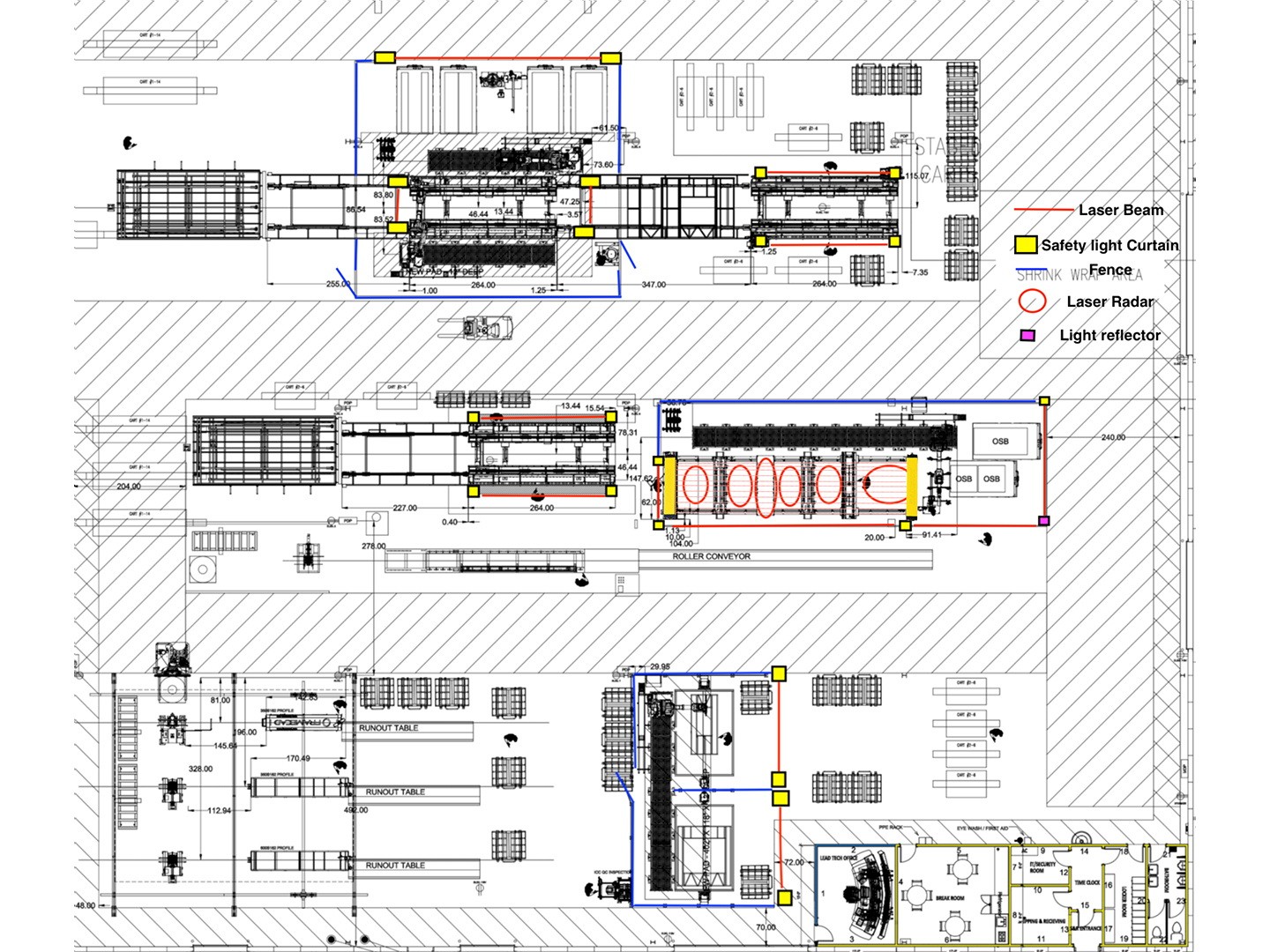

4. We learned from the customer's requirements that area 3 is the OSB equipment area. To prevent personnel and foreign objects from entering, it can form an area protection. We chose the light curtain refraction scheme and added a light reflector, among which beam

The pitch is 40mm. According to the working range of the corresponding equipment, the total length of light is 10m and the protection height is 1480mm, so the model QSA38/40-1480-A2L is determined.

5. After the customer understands the product function and determines the model, we prepare a 3D file of the product size for the customer, so that the product fits better with the customer's original mechanical design and ensures the smooth progress of the installation.

When you need to install a light curtain on an automation device, the following are some possible steps and suggestions:

1. Understand the equipment: Firstly, familiarize yourself with your automation equipment and its installation requirements. Refer to our product manual for the device or contact us to learn about the applicability and installation guidelines of the light curtain.

2. Determine location: Determine the location where you want to install the light curtain. This may require finding a suitable location on the device and ensuring that the light curtain can fully cover the required area.

3. Installation bracket: Install the bracket or fixing device according to the requirements of the optical equipment and its bracket. This will ensure that the light curtain is securely installed on the device.

4. Connect the power and data cables: Connect the power and data cables of the light curtain to the device. Ensure the correct power supply and cables are used, and follow the connection method between the device and the light curtain.

5. Installation and adjustment of the light curtain: Place the light curtain on a bracket and adjust it according to the equipment requirements. Ensure that the position and angle of the light curtain can effectively detect the required area.

6. Test function: After installation, perform a functional test of the light curtain. Trigger the light curtain and confirm that the device can correctly detect obstruction.

7. Regular maintenance: Regularly inspect and maintain the light curtain equipment to ensure its normal operation. Clean the surface of the light curtain and check if the connections and power cords are safe.

Before carrying out any installation tasks, please be sure to refer to the instructions for the equipment and light curtain, and strictly follow the installation guidelines and safety operating procedures. If you are unsure about the installation program, it is recommended to consult professional technical personnel or our support team for equipment.