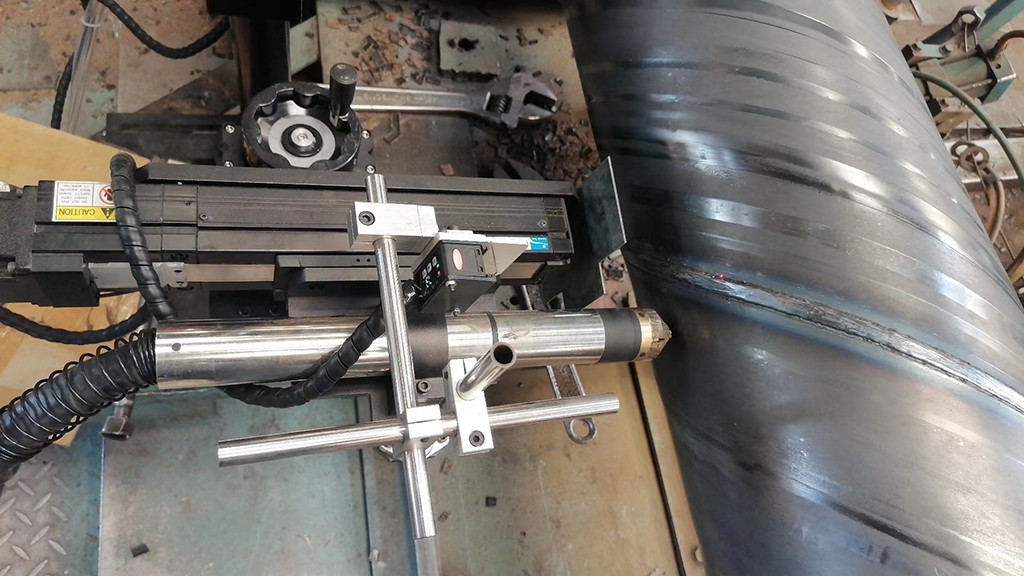

Auxiliary Equipment for Laser Pipe Cutting Machines in Cutting Spiral Welded Steel Pipes—Laser Displacement Sensors

The Main Challenges Faced by Laser Pipe Cutting Machines When Cutting Spiral Welded Steel Pipes

Enhancing Laser Pipe Cutting Efficiency: The Role of Laser Displacement Sensors in Spiral Welded Steel Pipe Processing

Recommended Laser Displacement Sensors

|

Sensing Distance

|

Repeatability

|

Linearity |

Output

|

|

30 mm (±5)

|

10 µm

|

±0.1%F.S. |

Analog / RS485

|

|

50 mm (±15)

|

30 µm

|

NPN / Analog / RS485

|

|

|

100 mm (±35)

|

70 µm

|

||

200 mm (±80) | 200 µm | ±0.2%F.S. | |

400 mm (±200) | 400 µm / 800 µm | ||

| |||

Laser displacement sensors are versatile measurement tools capable of accurately measuring physical quantities such as length, distance, vibration, speed, and angle. Laser displacement sensors play a crucial role in applications such as small part identification, conveyor belt monitoring, material overlap detection, robotic position control, liquid level monitoring, thickness measurement, vibration analysis, collision testing, and various automotive tests. | |||