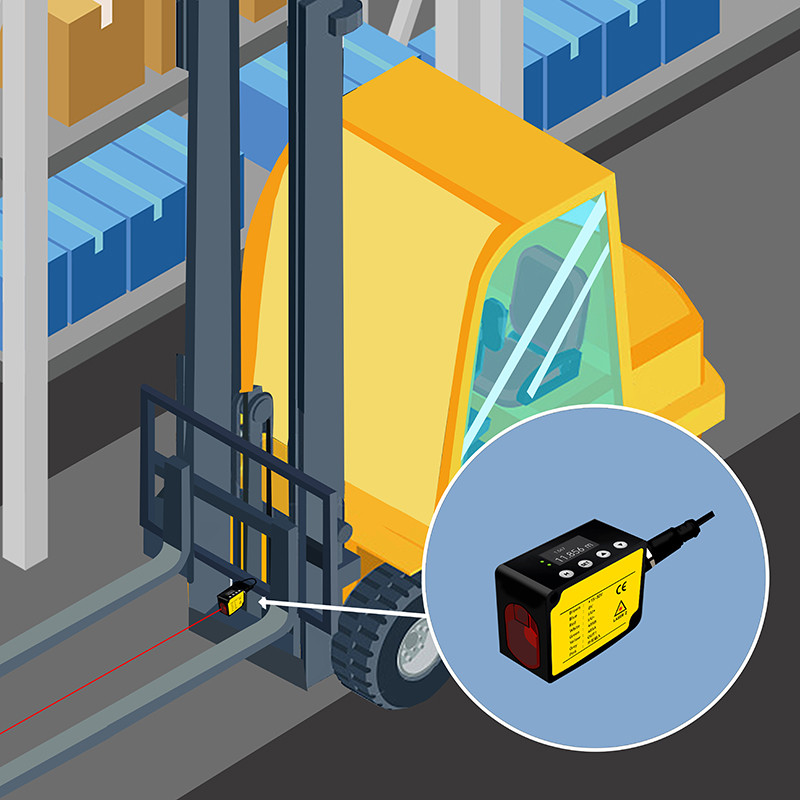

Optimizing Automatic Forklift Pallet Handling with TOF Phase-Shift Laser Distance Sensors

Optimizing Automatic Forklift Pallet Handling with TOF Phase-Shift Laser Distance Sensors

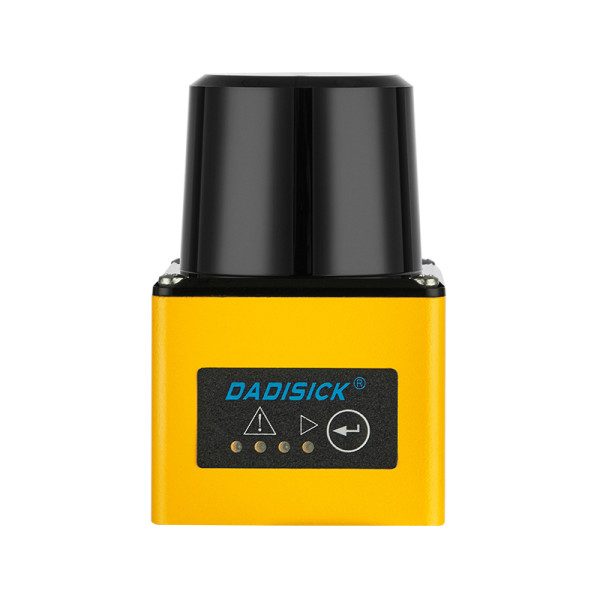

GFL-Y Series TOF Phase-Shift Laser Distance Sensor

GFL-Y Series Laser Distance Sensor

|

Model

|

|||

|

NPN+Analog+RS485

|

PNP+Analog+RS485

|

Measurement range

|

Accuracy |

|

GFL-Y01IU-485-N

|

GFL-Y01IU-485-P

|

0.1 - 1 m

|

± 2 mm |

|

GFL-Y02IU-485-N

|

GFL-Y02IU-485-P

|

0.1 - 2 m

|

|

GFL-Y05IU-485-N | GFL-Y05IU-485-P | 0.1 - 5 m | |

GFL-Y10IU-485-N | GFL-Y10IU-485-P | 0.1 - 10 m | |

GFL-Y20IU-485-N | GFL-Y20IU-485-P | 0.1 - 20 m | ± 3 mm |

GFL-Y50IU-485-N | GFL-Y50IU-485-P | 0.1 - 50 m | ± 6 mm |

GFL-Y Series Key Features

Application Scenarios

Automatic Forklift Applications