Using Safety Laser Scanners for Safety Zone Monitoring on Metal Cutting Conveyors

Risks Associated with Metal Cutting Machine Operation

Hazards from Debris and Sparks During the Cutting Process:

During the cutting process, the high-speed rotating cutting disc generates metal debris and sparks. These particles can scatter into the surrounding area, potentially striking workers and causing injuries such as cuts, burns, or even more severe harm.Mechanical Energy of the Cutting Disc and Its Drive Mechanism:

The cutting disc and its drive mechanism (e.g., motors, transmission systems) possess significant mechanical energy during operation. Improper handling by workers or equipment malfunctions may lead to disc rupture or ejection, resulting in serious mechanical injuries.Limitations of Traditional Safety Measures:

In environments with such potential risks, worker safety is a top priority. However, traditional safety measures, such as physical barriers or mechanical limit switches, may not always provide comprehensive protection.Safety Laser Scanners for Safety Zone Monitoring

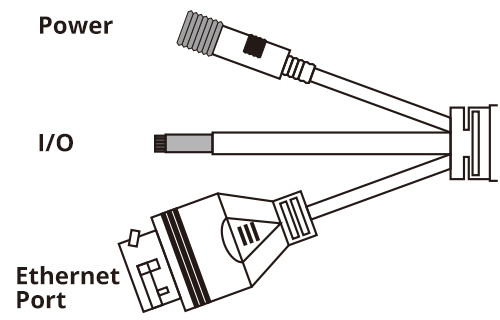

|

Socket

|

Type

|

Description

|

|

Power |

DC002

|

2-core

|

|

Ethernet Port |

RJ45 Socket

|

4-core

|

|

I/O |

SM2.45,5P

|

10-core

|