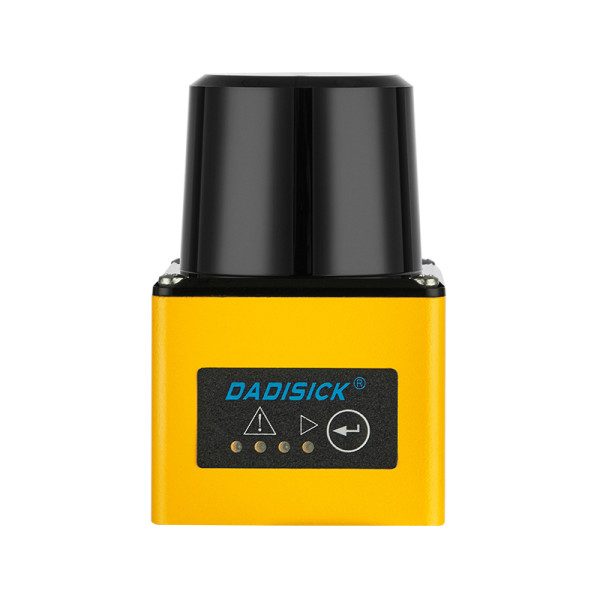

Collision Prevention Solution for Container Cranes Using LD-50G Safety Laser Scanner

Collision Prevention Solution for Container Cranes Using LD-50G Safety Laser Scanner

How Does the LD-50G Safety Laser Scanner Prevent Collision Accidents?

Key Features and Benefits of the LD-50G Safety Laser Scanner

|

Laser Wavelength

|

905 nm

|

|

|

Eye Safety Classification

|

Class 1 (IEC60825-1:2014)

|

|

|

Detection Range

|

20 m @ 10% reflectivity; 50 m @ 70% reflectivity

|

|

|

Measurement Accuracy

|

±2 cm

|

|

Scanning Angle | 270° | |

Sampling Frequency | 60 k | |

Angular Resolution | 0.06°@10Hz; 0.09°@15Hz; 0.12°@20Hz | |

Protection Level | IP65 | |

Operating Temperature | -20℃ to 60℃ | |

Storage temperature | -30°C to 80°C | |

Ambient Light Immunity | 80000 lux | |

Data interface | 100Mbps ethernet interface | |

Protocol | UDP | |

Power | 2.5 W | |

Operating Voltage | 9-32 V DC | |

Dimensions | 60 mm x 60 mm x 84.5 mm | |

Weight | 205 g | |

Real-World Application: Enhancing Safety and Efficiency at Global Container Terminals