Product News | User-Developable 2D Single-Line TOF Navigation & Measurement LiDAR

LiDAR Core Technology—HQPC

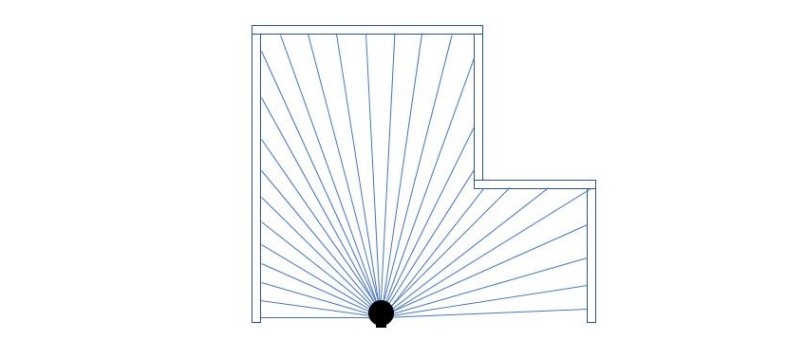

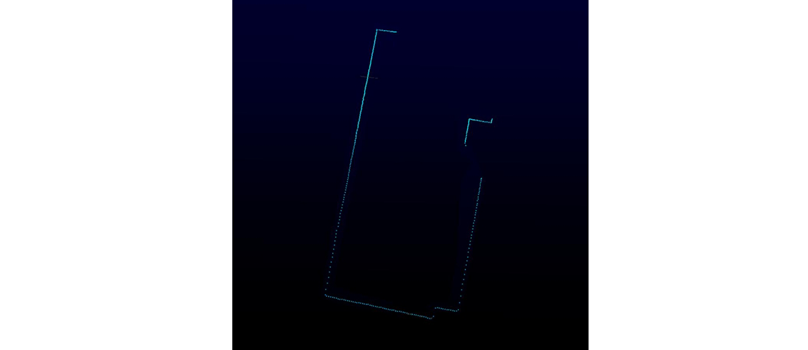

Single-line TOF Scanning Laser Radar Overview

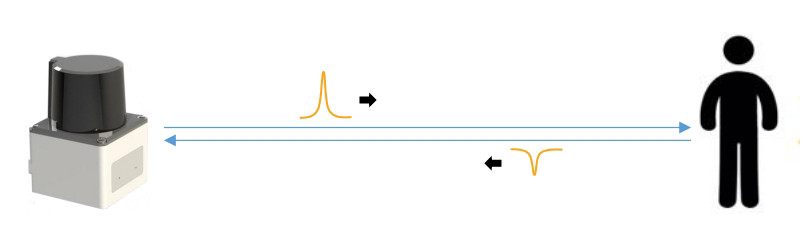

Working Principle

Recommend DADISICK TOF LiDAR

|

Basic Information

|

|||

Product Name | Single-line TOF Scanning Laser Radar | ||

|

Models

|

LD-10H

|

LD-20H |

LD-30H

|

Measurement Characteristics | |||

Detection Range @ 90% Reflectivity | 10 m | 20 m | 30 m |

Detection Range @ 10% Reflectivity | 5 m | 8 m | 10 m |

Measurement Accuracy | ±30 mm | ||

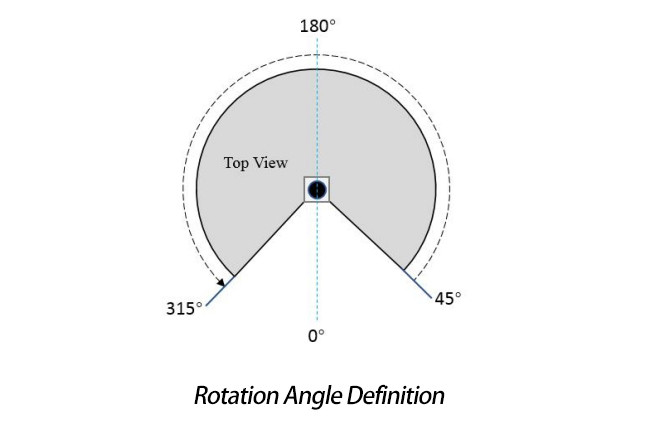

Scan Angle | 270° | ||

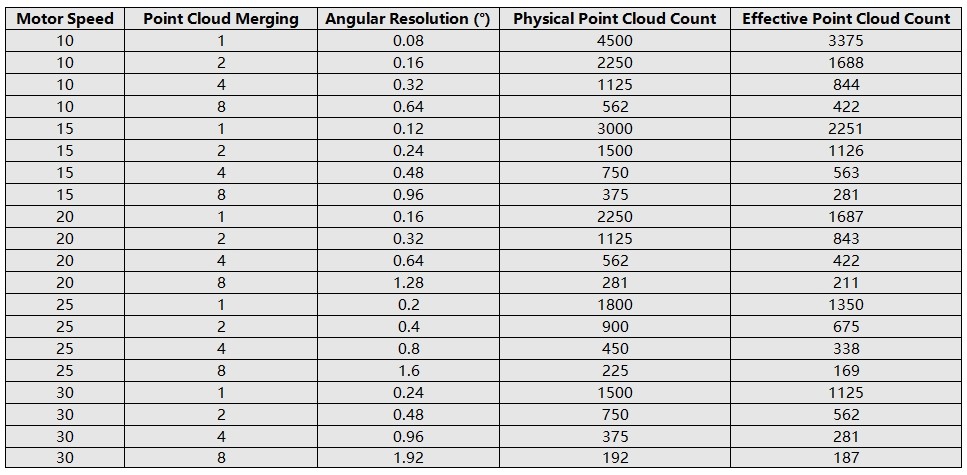

Point Cloud Merging | 1/2/4/8 points | ||

Scan Frequency | 10-30 Hz | ||

Minimum Angular Resolution | Min 0.08° (adjustable) | ||

Optoelectronic Characteristics | |||

Operating Voltage | DC12 V - 24 V | ||

Operating Current | 0.21 A/12 V (typical) | ||

|

Laser Source

|

905 nm, class I

|

||

Power Consumption | 2 W | ||

Other | |||

Data Transmission Interface | Ethernet 100BASE-TX | ||

Startup Time | < 10 s | ||

Indicators | Power indicator light / Status indicator light | ||

Ambient Light Resistance | > 50,000 lux | ||

Operating Temperature | -10 °C to +55 °C | ||

Storage Temperature | -30 °C to +75 °C | ||

Humidity | < 80% | ||

Service Life | 5 years (without battery) | ||

Vibration Resistance | |||

Vibration | 10-55 Hz, amplitude 0.75 mm, XYZ axes, each axis 2 hours; 50-200 Hz, 196 m/s² (20G), scan frequency 2 min/cycle, XYZ axes, each axis 4 hours. | ||

Protection Level | IP65 | ||

Dimensions | 50 × 50 × 76 mm | ||

Weight | 148 g (excluding cable) | ||